Pine Mountain Settlement School

Series 17: PUBLICATIONS PMSS

Workbook for Students of Printing

1942

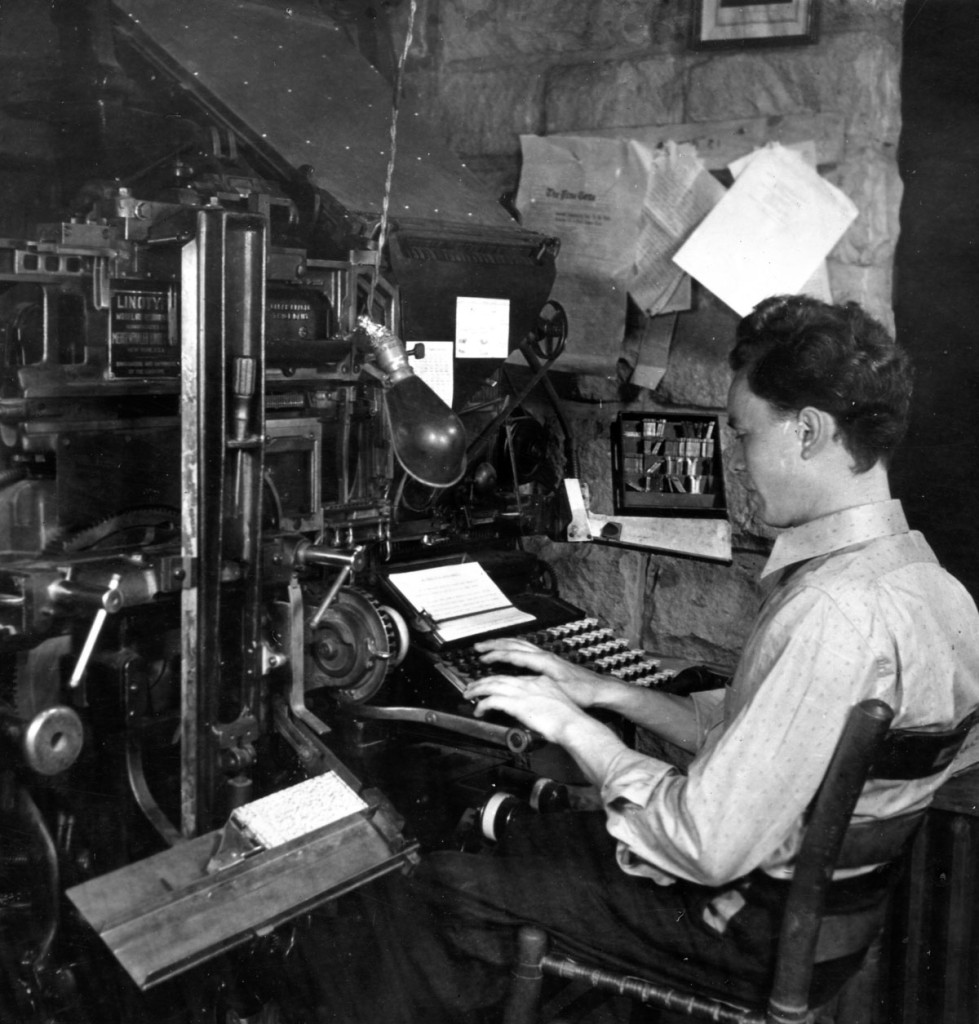

Print Shop, c. 1942: Student at Linotype. Harmon Fdn. movie still. [pm_harm_095.jpg]

TAGS: PMSS publications, Workbook for Students of Printing, PMSS print shop, printing presses, letterpress process, Linotype, August Angel, safety and policy manual, The Practice of Printing, typesetting

PUBLICATIONS PMSS Workbook for Students of Printing 1942

The Workbook for Students of Printing was prepared in 1942 by August Angel, (printing and science teacher) to train students in the operation of the Pine Mountain Settlement School press. It also served as a manual for safety and policy in the Print Shop.

This is the second workbook written by Mr. Angel, and explained to the student how to “lock up a form for a platen press and produce a complete printed job.” The first workbook was concerned with “producing a clean, perfect job of straight-matter typesetting,” with most of the printing done on the hand proof press.

Both workbooks were designed to be used in conjunction with a formal textbook on the subject, The Practice of Printing, by Ralph W. Polk (published by Manual Arts Press, Peoria, 1937.)

CONTENTS

workbook ; printing students ; school print shop ; typesetting ; hand proof press ; form ; platen press ; print job ; dead linotype form ; imposing stone ; imposing table ; chase ; furniture ; text books ; quoins ; locking the form ; quoin key ; planing ; mallet ; planer ; suggested reading ; The Practice of Printing ; Polk ; assignments ; chaser method ; work and turn job ; sheetwise ; layout ; printing presses ; letterpress process ; foundry type ; Linotype ; type-high printing plates ; platen presses ; cylinder presses ; rotary presses ; Chandler and Price Gordon ; Colt Armory Press ; automatic mechanical feeder ; ink rollers ; summer rollers ; winter rollers ; oiling a press ; make-ready ; inking a press ; pressfeeder ; even color ; press feeding ; fanning out sheets ; grippers ; hard packing ; soft packing ; tympan-sheet ; offsetting ; slip-sheeting ;

GALLERY: Workbook for Students of Printing

- Cover Page — Workbook for Students of Printing by August Angel, 1942. [angel_0051.jpg]

- Title Page — Workbook for Students of Printing by August Angel, 1942. [angel_0061.jpg]

- Copyright Page – Workbook for Students of Printing by August Angel, 1942. [angel_0071.jpg]

- Page 3 — Workbook for Students of Printing by August Angel, 1942. [angel_0081.jpg]

- Page 4 — Workbook for Students of Printing by August Angel, 1942. [angel_0091.jpg]

- Page 6 — Workbook for Students of Printing by August Angel, 1942. [angel_0101.jpg]

- Page 7 — Workbook for Students of Printing by August Angel, 1942. [angel_0111.jpg]

- Page 8 — Workbook for Students of Printing by August Angel, 1942. [angel_0121.jpg]

TRANSCRIPTION: PUBLICATIONS PMSS Workbook for Students of Printing

[angel_005, cover]

WORKBOOK FOR STUDENTS OF PRINTING

by August Angel

PINE MOUNTAIN SETTLEMENT SCHOOL

PINE MOUNTAIN, HARLAN COUNTY, KENTUCKY

[angel_006, page 1]

WORKBOOK FOR STUDENTS OF PRINTING

by August Angel

PINE MOUNTAIN SETTLEMENT SCHOOL

PINE MOUNTAIN, HARLAN COUNTY, KENTUCKY

[angel_007, page 2]

Copyright, 1942, by August Angel

[angel_008, page 3]

THE JOB OF PRINTING

ONE OF THE PURPOSES of this workbook, your second in printing, is to provide material to study further the art and science of printing. Along with formal book study you will have a chance, because of the possibilities and opportunities for practice in the school print shop, to acquire knowledge and skills in printing so that in time you will be able to do a fairly expert piece of work on a small printing job.

In your first workbook you were concerned mostly with producing a clean, perfect job of straight-matter typesetting and most of your printing was done on the hand proof press: Now, you are ready to lock up a form for a platen press and produce a complete printed job.

Obtain a dead Linotype form and place it on the imposing stone or table. Be sure the steel top of the imposing table is clean by wiping off the surface with a clean rag.

Place a chase on the imposing table so that the form to be printed is about in the center of the chase. Lock the form in the chase by placing furniture around the form. Proper methods are show in several of the printing text books on the book shelf. You may also have observed the instructor or other advanced students locking up a form in a chase. Use quoins (pronounced coins) to lock the form. Always use quoins so that they will press the form toward the solid part of the chase. It is a rule in all shops that the inside quoins must always point toward the solid side of the chase.

Before a form is locked snugly into proper position, all matter in the form should be in alignment and all lines the same length. The quoins should be pushed together firmly with the fingers, or given a slight turn with the quoin key, but not enough to lock up the form tightly because the form must be planed with a mallet or a planer to level the type form. If the quoins are too tight this planing is not possible. NEVER PLANE A LOCKED FORM. After a form is planed, it may be locked up tightly for…

[angel_009, page 4]

…the press. Always have the instructor check up your locked form before placing it in the press.

Suggested Reading: Chapter 13 – The Practice of Printing – Polk

WORK TO BE DONE:

1. On blank pages above and following draw a diagram of the proper method of locking up a type form when form is exact width of furniture; (b). when a form is built out to a standard length of furniture; (c). when you are using a chaser method of locking up a form.

2. Draw a diagram showing proper positions of the inner quoin in a chase.

3. What is the meaning of imposition of form?

4. What is a work and turn job?

5. What is a job printed sheetwise?

6. Draw two diagrams of printing a four-page folder, work-and-turn.

7. Draw a diagram for the lay-out of an eight-page folder printed sheetwise.

[angel_010, page 6 (sic)]

PRINTING PRESSES

Printing in our shop is done by the letterpress process, in which impressions are made from raised surfaces, such as from foundry type, Linotype or type-high printing plates.

Printing presses for letterpress work are of three main types: (a) platens, (b) cylinders, and (c) rotary presses.

The platen press. In our shop there are two platen presses 10×15 and 14×22 of the Chandler and Price Gordon manufacture. They are easy machines to operate and are capable of a wide range of work.

Suggested Reading: Chapter 14 – The Practice of Printing – Polk

WORK TO BE DONE;

1. Draw a diagram of the three main types of printing presses that use the letterpress idea.

2. What is the Colt Armory Press?

3. Describe a cylinder press. How does it work to produce a printed sheet?

4. Tell something of a rotary press.

5. What is an automatic mechanical feeder?

6. Name the important parts of a Gordon press.

7. What are ink rollers made of?

8. What is a “summer roller”? How is a “summer roller” different from a “winter roller”?

9. What is a very important rule regarding the oiling of a press?

[angel_011, page 7]

MAKE-READY and FEEDING A PRESS

You should at this time be fairly well acquainted with the press and be able to proceed alone with the printing of small jobs.

How to ink the press. Be sure the press is clean. There should be no oil on the disk or rollers. Put a small amount of ink, about the size of a large bean, on the ink disk. Run the press slowly until all the ink is distributed all over the disk. Do not put too much ink on the disk, it is easier to add ink than to remove it.

Always ink up without a chase in the press. After the form has been run and more ink is needed it may be added in small amounts. The pressfeeder should keep an even “color” on his job. He should watch the impressions from time to time and add ink as needed.

Make Ready: When the form is first put in the press, an impression is taken on the draw sheet and often the tympan must be regulated so all parts of the form will print with a firm, even pressure.

The make-ready of the various kinds of forms in our school print shop is a very intricate process which the student will learn from reading books regarding impression and make-ready, watching the instructor and by actual practice at the press.

A student can learn to feed the press with little or not trouble. But there are some things he should observe in order to become expert at press feeding. (1) Fan out the pile of paper so each sheet can be picked up easily. (2) Keep in rhythm of the press. (3) Do not expect to run the press at full speed until you have formed the proper habits in mechanics of feeding. (4) Do not touch freshly printed parts of the paper.

Suggested Reading: Chapter 15 – The Practice of Printing – Polk

[angel_012, page 8]

WORK TO BE DONE: Answer the following questions.

1. What is the meaning of color on the job?

2. What is the reason for being careful in regard to the grippers when putting the form in the press?

3. What is hard and soft packing?

4. Briefly, how are paper guides placed on the tympan-sheet?

5. What is the cause of offsetting?

6. What is slip-sheeting?

See Also:

AUGUST ANGEL Staff – Biography

PRINT SHOP

PUBLICATIONS

Return To:

ADMIN GENERAL Rules and Regulations Guide